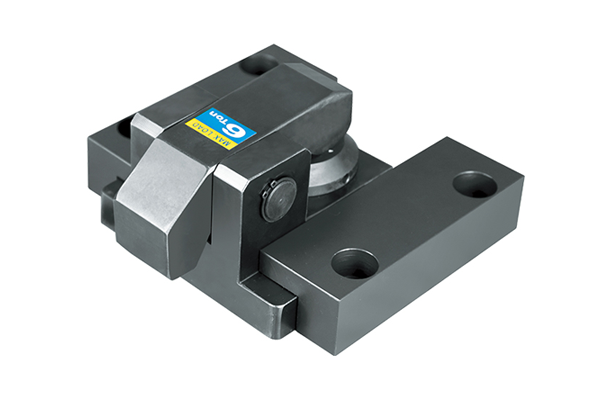

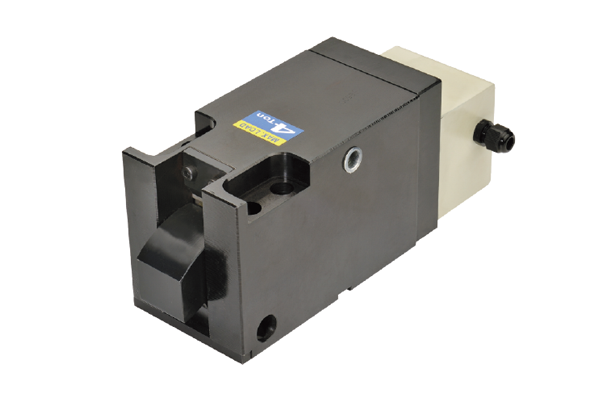

THL Die Clamp

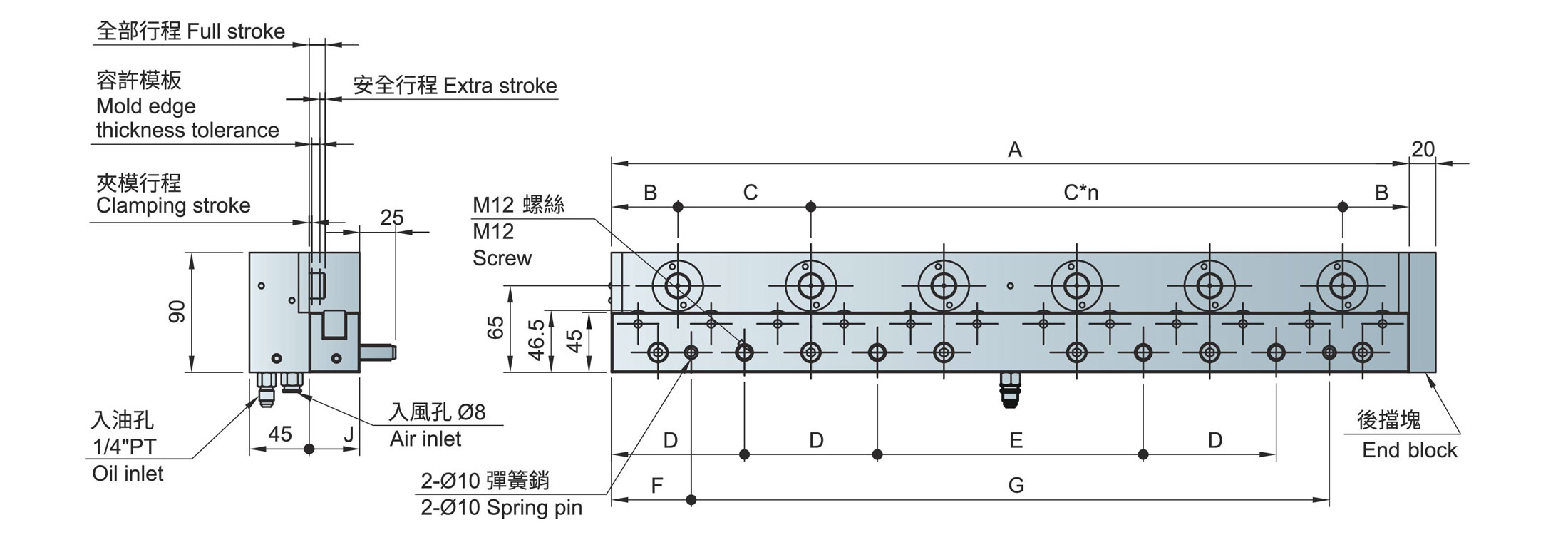

This roller-type clamping device has the function of roller and clamping mold, and it’s suitable for middle & small injection molding machines.

Specifications

| Model | Unit | THL_300-3 | THL_400-4 | THL_600-6 |

|---|---|---|---|---|

| Clamping Force ( at 250 kg / cm2 ) | tons | 3 | 4 | 6 |

| Overall Length | mm | 300 | 400 | 600 |

| Cylinder Q’ty | pcs | 3 | 4 | 6 |

| Full Stroke | mm | 12 | 12 | 12 |

| Clamping Stroke | mm | 2 | 2 | 2 |

| Mold Edge Thickness Tolerance | mm | ±3 | ±3 | ±3 |

| Extra Stroke | mm | 4 | 4 | 4 |

| Cylinder Capacity st Full Stroke | cc. | 1.4 | 1.4 | 1.4 |

| Roller Q’ty | pcs | 6 | 8 | 12 |

| Mold Load Capacity(H=25~45 mm) | kg | 480 | 640 | 960 |

| Mold Load Capacity(H=45~60 mm) | kg | 1200 | 1600 | 2400 |

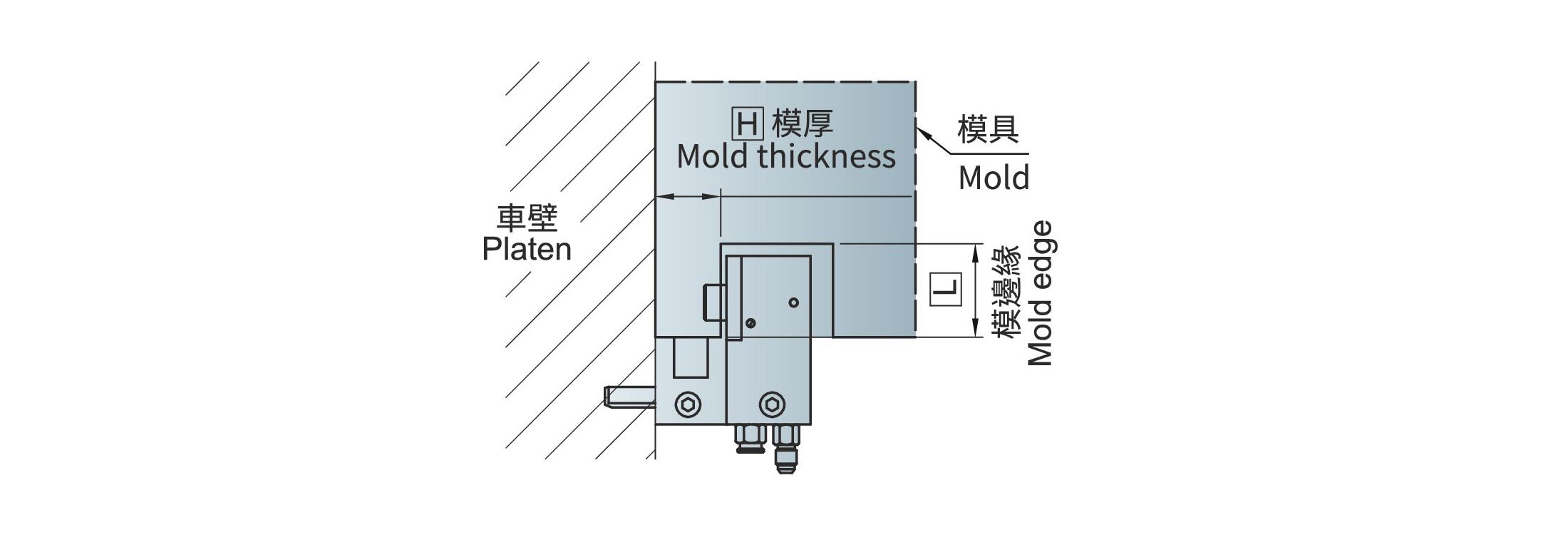

Mold size should cover on all cylinders to achieve enough clamping force.

| Model | A | B | C | D | E | F | G | min.H | min.K |

|---|---|---|---|---|---|---|---|---|---|

| THL_300-3 | 300 | 50 | 100 | 100 | 100 | 60 | 180 | 25 | 45 |

| THL_400-4 | 400 | 50 | 100 | 100 | 200 | 60 | 280 | 25 | 45 |

| THL_600-6 | 600 | 50 | 100 | 100 | 200 | 60 | 480 | 25 | 45 |

Holes setting (D、E、F、G)is adjustable.

Dimension J varies depending on mold thickness.