A Detailed Look into Quick Mold Change Systems

Within the realm of manufacturing, injection molding has established itself as a highly popular and effective technique. However, as the demand in the industry rises, so does the need for quick and efficient production methods. Enter Quick Mold Change System (QMCS), a technological advancement that brings a new level of efficiency to injection molding processes. But what exactly is a QMCS, and how is it revolutionizing the injection molding landscape? This blog post will provide a detailed overview of QMCS, elucidating its components, benefits, and undeniably significant role in the future of manufacturing. So, if you're a part of the manufacturing world or simply intrigued by its nuanced processes, let us fully unravel the fascinating world of Quick Mold Change Systems.

The Purpose and Benefits of Quick Mold Change Systems

In essence, a Quick Mold Change System is designed to reduce the time spent replacing molds during the production process. Traditional mold replacement techniques are time-consuming and labor-intensive, diminishing the overall efficiency of the manufacturing process. Conversely, QMCS introduces a way to mitigate these challenges.

Adopting QMCS comes with a variety of benefits that directly impact a company's bottom line. The most significant one is minimizing downtime. With QMCS, the time spent during mold changes can be drastically reduced. Furthermore, QMCS offers enhanced versatility for small batch runs, providing an edge for companies navigating the demand for product diversity. The system also facilitates speedier product deliveries and an improved standard of quality, thanks to the precision of automated mechanisms. Overall, the QMCS revolutionizes traditional production processes, ushering manufacturers into a new age of efficiency.

Components of Quick Mold Change Systems

Understanding the key components of a QMCS plays a vital role in recognizing its potential. Major components include mold clamps, power units, and mold carts.

Major components include mold clamps, power units, and mold carts. Mold clamps are particularly integral to a QMCS's operation, and we've covered everything you need to know about these systems in our comprehensive blog post on Everything You Need to Know About Mold Clamping Systems.

|

|

|

Buying Guide for Quick Mold Change Systems

When investing in a QMCS, there are specific factors to consider to ensure the chosen system meets specific manufacturing requirements and objectives. The first one is adaptability, ensuring the chosen QMCS can fit seamlessly into existing production processes.

Additionally, company’s should consider the system’s durability and longevity, the ease of maintenance, and importantly, the brand’s post-sale support. Verifying these details before purchase can lead to the selection of a QMCS that matches both the current and future needs of the company.

Case Study: Foxconn's Experience with Quick Mold Change Systems

A real-world example allows us to comprehend the benefits of a QMCS in action. Foxconn, an industry player, represents just that. After the integration of QMCS into their manufacturing process, Foxconn observed significant improvements in efficiency and profitability. The switchover to automated mold changing was a game-changer for the company, underscoring the potential benefits for manufacturers worldwide aiming to modernize their operations.

Clientele Experiences and Positive Feedback

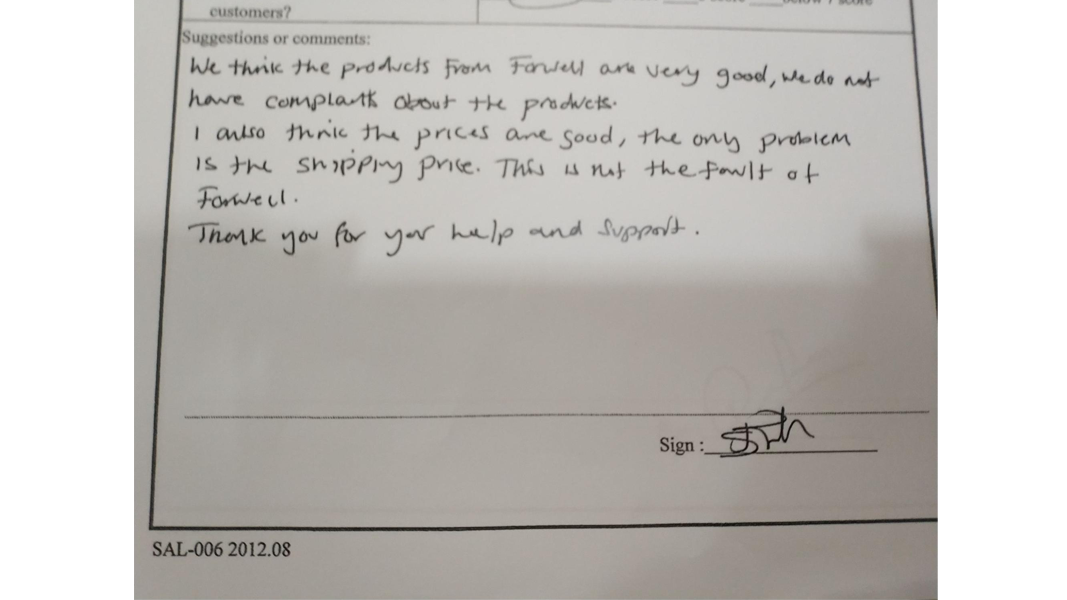

As a leading provider of Quick Mold Change Systems, we are proud to have served countless customers across the globe. The testimonials we receive regularly speak to our commitment to quality and efficiency.

Our diversified customer base ranges from small local businesses to large multinational corporations, all of whom have significantly benefited from our QMC systems. They acknowledge that our solutions have helped reduce setup times, increase machinery productivity, and amplify overall operational efficiency.

Here is what one of our customers have to say about our Quick Mold Change Systems:“We think the products from Forewell are very good, we do not have complaints about the products. I also think the prices are good.” - A leading Company from Mid-East Countries.

The Need for Automation

The quick pace at which technology accelerates leaves no room for manual, time-consuming procedures. As we move into the future, automated systems like QMCS will be more common in the manufacturing industry, highlighting an immediate need for companies to adapt.

Transitioning to advanced automated systems such as QMCS should not be seen as an option, but a necessity for sustaining competition and ensuring progress within the rapidly evolving manufacturing landscape.

Revolutionize Your Production Line with FOREWELL's Quick Mold Change Systems

In conclusion, Quick Mold Change Systems offer an innovative solution for companies seeking to enhance their manufacturing efficiency while ensuring product quality. Its strategic adoption promises heightened profitability and future-readiness for manufacturing. As we move more into an era of automation and technological evolution, consider QMCS as your partner in navigating the future of manufacturing and staying ahead of your competition.

We understand that you may have more questions or need further clarification on how Quick Mold Change Systems can benefit your processes. Don't hesitate to reach out. Visit our Contact Us page and leave us an inquiry. Our experts are ready and willing to assist you towards a future of streamlined efficiency and productivity.

Previous page