Company Profile

Creator comprehensive mold management integrated systems

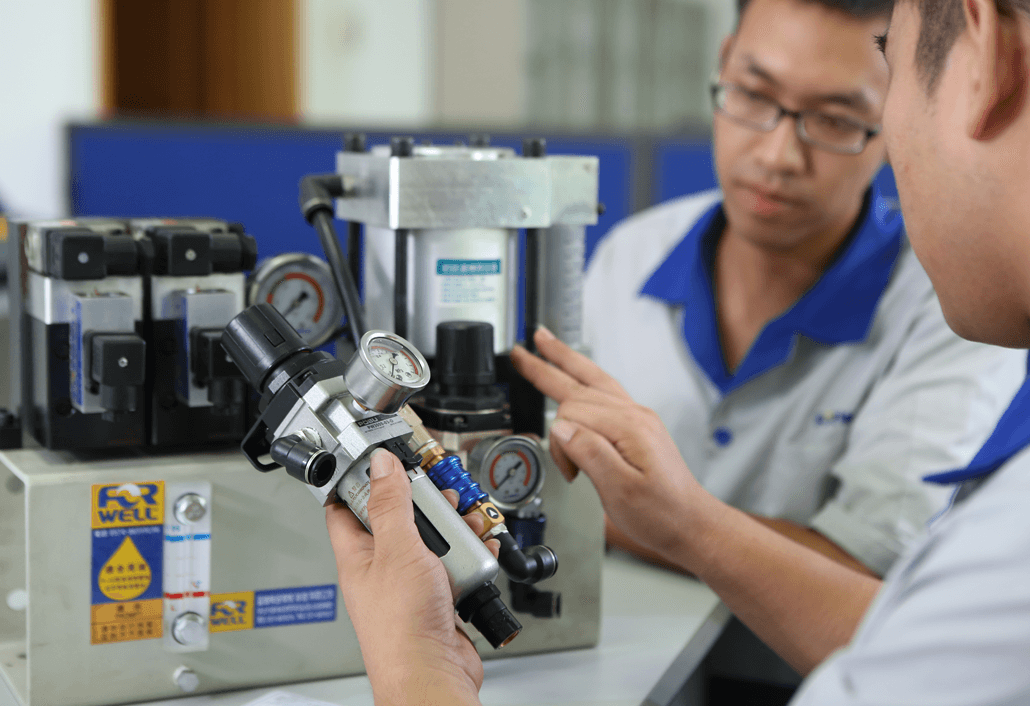

Forwell Machinery Co. Ltd., was established in 1987 and specializes in the production of quick die/mold change systems, die/mold cart systems, PCB fine piercing systems and automatic die clamping systems. The wide range of customizable quick change systems and automatic clamping systems can be used for many different types of machines such as: press machines (mechanical and hydraulic types), plastic injection molding machines and die casting machines.

Forwell has been widely acknowledged for the high quality and functionality of their products. With a strong emphasis on research and development, the core principles of quality, service and innovation are strongly enforced, fostering the development of innovative customized products in line with customer requirements.

Thanks to a strong performance and an increasing customer base, Forwell has a strong global presence and is the manufacturer of quick die/mold change systems both in Taiwan and mainland China. Furthermore a gigantic 12,000 square meter factory is under construction, and is due for completion in 2015 in Jiangsu, China. This plant will focus on strengthening Forwell’s R&D capabilities and driving substantial business growth in the years to come.